What Is Art Made of Springs and Gears Called

An uncoiled mod spotter mainspring.

Keys of various sizes for winding up mainsprings on clocks.

A mainspring is a screw torsion spring of metal ribbon—commonly bound steel—used equally a ability source in mechanical watches, some clocks, and other clockwork mechanisms. Winding the timepiece, by turning a knob or primal, stores energy in the mainspring by twisting the spiral tighter. The forcefulness of the mainspring so turns the clock's wheels as it unwinds, until the next winding is needed. The adjectives air current-up and spring-powered refer to mechanisms powered past mainsprings, which too include kitchen timers, metronomes, music boxes, wind-up toys and clockwork radios.

Modernistic mainsprings [edit]

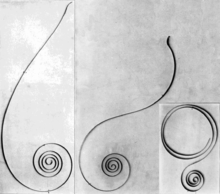

Elgin pocketwatch mainsprings from around 1910, showing the 3 types (fifty-r): spiral, semi-reverse, reverse.

A modernistic spotter mainspring is a long strip of hardened and blued steel, or specialised steel alloy, xx–xxx cm long and 0.05-0.2 mm thick. The mainspring in the mutual 1-day movement is calculated to enable the watch to run for 36 to forty hours, i.eastward. 24 hours betwixt daily windings with a power-reserve of 12 to 16 hours, in case the owner is tardily winding the watch. This is the normal standard for paw-wound as well as self-winding watches. viii-Day movements, used in clocks meant to exist wound weekly, provide power for at least 192 hours merely use longer mainsprings and bigger barrels. Clock mainsprings are similar to watch springs, simply larger.

Since 1945, carbon steel alloys accept been increasingly superseded by newer special alloys (iron, nickel and chromium with the addition of cobalt, molybdenum, or beryllium), and also by cold-rolled alloys ('structural hardening'). Known to watchmakers as 'white metal' springs (every bit opposed to blued carbon steel), these are stainless and have a higher elastic limit. They are less subject area to permanent bending (condign 'tired') and there is scarcely any risk of their breaking. Some of them are also practically not-magnetic.

In their relaxed course, mainsprings are made in three distinct shapes:

- Screw coiled: These are coiled in the same direction throughout, in a simple spiral.

- Semi-reverse: The outer end of the spring is coiled in the reverse direction for less than one turn (less than 360°).

- Reverse (resilient): the outer end of the spring is coiled in the contrary management for one or more turns (exceeding 360°).

The semi-reverse and reverse types provide extra force at the end of the running period, when the spring is almost out of energy, in order to keep the timepiece running at a constant rate to the end.

How they piece of work [edit]

Mainspring in a 1950s alarm clock. The end of the jump is fastened to the frame post at lower right.

Cross department of a going barrel in a watch (mainspring fully wound).

Going barrel of a sentry, opened.

The mainspring is coiled effectually an axle called the arbor, with the inner end hooked to it. In many clocks, the outer terminate is attached to a stationary post. The spring is wound upwards by turning the arbor, and after winding its force turns the arbor the other way to run the clock. The disadvantage of this open up spring arrangement is that while the mainspring is beingness wound, its bulldoze force is removed from the clock motility, so the clock may stop. This type is oftentimes used on alarm clocks, music boxes and kitchen timers where it doesn't matter if the mechanism stops while winding. The winding mechanism always has a ratchet attached, with a pawl (called past clockmakers the click) to prevent the bound from unwinding.

In the form used in modern watches, called the going barrel, the mainspring is coiled effectually an arbor and enclosed inside a cylindrical box called the barrel which is free to turn. The jump is attached to the arbor at its inner end, and to the butt at its outer end. The attachments are small hooks or tabs, which the leap is hooked to by foursquare holes in its ends, so information technology can exist easily replaced.

The mainspring is wound past turning the arbor, but drives the watch motility past the butt; this arrangement allows the leap to go along powering the watch while it is being wound. Winding the sentinel turns the arbor, which tightens the mainspring, wrapping information technology closer around the arbor. The arbor has a ratchet attached to information technology, with a click to forestall the spring from turning the arbor astern and unwinding. After winding, the arbor is stationary and the pull of the mainspring turns the butt, which has a ring of gear teeth effectually information technology. This meshes with one of the clock's gears, normally the center bike pinion and drives the bicycle train. The butt ordinarily rotates once every 8 hours, so the mutual xl-hr jump requires 5 turns to unwind completely.

Hazards [edit]

The mainspring contains a lot of free energy. Clocks and watches accept to be disassembled periodically for maintenance and repair, and if precautions are non taken the bound can release all of a sudden, causing potentially serious injury. Mainsprings are 'let downwardly' gently before servicing, by pulling the click back while holding the winding key, allowing the spring to slowly unwind. However, even in their 'permit down' land, mainsprings contain dangerous residual tension. Watchmakers and clockmakers use a tool called a "mainspring winder" to safely install and remove them. Large mainsprings in clocks are immobilized by "mainspring clamps" before removal.

History [edit]

Mainsprings appeared in the first spring-powered clocks, in 15th-century Europe. It replaced the weight hanging from a cord wrapped effectually a pulley, which was the ability source used in all previous mechanical clocks. Around 1400 coiled springs began to be used in locks,[one] and many early clockmakers were also locksmiths.[2] Springs were practical to clocks to make them smaller and more portable than previous weight-driven clocks, evolving into the first pocketwatches past 1600. Many sources erroneously credit the invention of the mainspring to the Nuremberg clockmaker Peter Henlein (also spelled Henle, or Hele) effectually 1511.[3] [4] [five] However, many references in 15th-century sources to portable clocks 'without weights', and at least two surviving examples, prove that spring-driven clocks existed by the early on years of that century.[1] [6] [7] The oldest surviving clock powered by a mainspring is the Burgunderuhr (Burgundy Clock), an ornate, gilded chamber clock, currently at the Germanisches Nationalmuseum in Nuremberg, whose iconography suggests that it was made around 1430 for Philip the Good, Knuckles of Burgundy.[one]

The first mainsprings were made of steel without tempering or hardening processes. They didn't run very long, and had to be wound twice a day. Henlein was noted for making watches that would run forty hours between windings. The 18th century methods of making mainsprings are described past Berthoud[8] and Blakey[9]

Constant force from a spring [edit]

Torque curve of a mainspring. The force (torque) it provides decreases linearly as it unwinds.

Torque curves of mainsprings in going barrels (1879). The flatter central section provides more constant force during the running period, allowing the clock movement to keep amend time.

A trouble throughout the history of spring-driven clocks and watches is that the force (torque) provided by a spring is not constant, merely diminishes as the leap unwinds (see graph). However, timepieces take to run at a constant rate in order to keep authentic fourth dimension. Timekeeping mechanisms are never perfectly isochronous, meaning their rate is affected by changes in the drive force. This was especially truthful of the primitive verge and foliot type used before the appearance of the balance jump in 1657. So early clocks slowed down during their running period equally the mainspring ran downward, causing inaccurate timekeeping.

Ii solutions to this problem appeared in the early on spring-powered clocks in the 15th century; the stackfreed and the fusee:

Stackfreed [edit]

The stackfreed was an eccentric cam mounted on the mainspring arbor, with a leap-loaded roller that pressed against information technology. The cam had a 'snail' shape and then that early in the running menstruum when the mainspring was pushing strongly, the spring would bear confronting the wide part of the cam, providing a potent opposing strength, while later in the running menses every bit the forcefulness of the mainspring decreased, the spring would bear confronting the narrower part of the cam and the opposing forcefulness would also decrease. The stackfreed added a lot of friction and probably reduced a clock's running fourth dimension substantially; information technology was only used in some German timepieces and was abandoned after about a century.

Fusee [edit]

The fusee was a much longer-lasting innovation. This was a cone-shaped pulley that was turned past a chain wrapped effectually the mainspring butt. Its curving shape continuously changed the mechanical advantage of the linkage to even out the force of the mainspring every bit it ran downward. Fusees became the standard method of getting abiding torque from a mainspring. They were used in nigh jump-driven clocks and watches from their first appearance until the 19th century when the going barrel took over, and in marine chronometers until the 1970s.

Stopwork [edit]

Another early device which helped even out the spring's force was stopwork or winding stops, which prevented the mainspring from being wound up all the fashion, and prevented it from unwinding all the manner. The idea was to use only the primal part of the spring's 'torque curve', where its force was more constant. The well-nigh common form was the Geneva stop or 'Maltese cross'. Stopwork isn't needed in modern watches.

Remontoire [edit]

A fourth device used in a few precision timepieces was the remontoire. This was a minor secondary spring or weight which powered the timepiece's escapement, and was itself rewound periodically by the mainspring. This isolated the timekeeping chemical element from the varying mainspring force.

Going barrel [edit]

The modern going barrel, invented in 1760 by Jean-Antoine Lépine, produces a constant force by but using a longer mainspring than needed, and coiling information technology nether tension in the barrel. In functioning, but a few turns of the spring at a time are used, with the balance pressed against the outer wall of the butt. Mathematically, the tension creates a 'flat' department in the leap's 'torque bend' (meet graph) and only this flat section is used. In add-on, the outer terminate of the spring is often given a 'reverse' bend, so it has an 'S' shape. This stores more than tension in the spring's outer turns where it is available toward the end of the running period. The result is that the barrel provides approximately constant torque over the sentry'due south designed running period; the torque doesn't decline until the mainspring has virtually run down.

The built-in tension of the jump in the going butt makes it chancy to disassemble even when non wound up.

Cleaved mainsprings [edit]

Considering they are subjected to constant stress cycles, up until the 1960s mainsprings more often than not bankrupt from metallic fatigue long before other parts of the timepiece. They were considered expendable items.[10] This frequently happened at the end of the winding process, when the jump is wound every bit tightly equally possible effectually the arbor, with no space between the coils. When manually winding, information technology is easy to reach this point unexpectedly and put excessive pressure level on the spring. Some other cause was temperature changes. If a sentry was fully wound in the evening and the temperature dropped at night, without whatsoever slack between the coils the thermal contraction of the long spring could break it loose from its attachments at one finish. In before times, watch repairers noted that changes in the weather condition brought in a rash of watches with cleaved mainsprings. Broken mainsprings were the largest crusade of scout repairs until the 1960s.[11] Since then, the improvements in spring metallurgy mentioned above accept made broken mainsprings rare.

'Knocking' or 'banking' [edit]

Even if the mainsprings were not prone to breakage, besides much force during winding caused another problem in early watches, called 'knocking' or 'cyberbanking'.[12] [13] If very lilliputian slack was left in the spring afterward winding ('overwinding"), the pressure of the last plow of the winding knob put the terminate of the bound under excessive tension, which was locked in by the last click of the ratchet. And then the scout ran with excessive drive force for several hours, until the actress tension in the end of the spring was relieved. This made the balance cycle rotate also far in each direction, causing the impulse pin on the wheel to knock against the back of the fork horns. This caused the watch to proceeds time, and could suspension the impulse pin. In older watches this was prevented with 'stopwork'. In modern watches this is prevented by designing the 'click' with some 'recoil' (backlash), to permit the arbor to rotate backward after winding by about two ratchet teeth, enough to remove excess tension.

Motor or safety barrel [edit]

Effectually 1900, when broken watchsprings were more of a problem, some pocketwatches used a variation of the going butt chosen the motor barrel or prophylactic barrel. Mainsprings unremarkably broke at their attachment to the arbor, where bending stresses are greatest. When the mainspring broke, the outer function recoiled and the momentum spun the barrel in the opposite direction. This applied great forcefulness to the fragile wheel train and escapement, often breaking pivots and jewels.

In the motor barrel, the functions of the arbor and butt were reversed from the going barrel. The mainspring was wound past the barrel, and turned the arbor to drive the cycle train. Thus if the mainspring broke, the destructive recoil of the barrel would be applied not to the bike train but to the winding mechanism, which was robust enough to take it.

Prophylactic pinion [edit]

A prophylactic pinion was an alternate means of protection, used with the going barrel. In this, the center bike pinion, which the barrel gear engages, was attached to its shaft with a reverse spiral thread. If the jump broke, the reverse recoil of the barrel, instead of being passed on to the gear train, would simply unscrew the pinion.

The myth of 'overwinding' [edit]

Watches and clocks are oftentimes institute stopped with the mainspring fully wound, which led to a myth that winding a leap-driven timepiece all the style upwards damages it.[14] Several issues tin can cause this blazon of breakup, but information technology is never due to "overwinding", equally timepieces are designed to handle being wound up all the way.[14]

One crusade of "overwinding" is dirt. Watch movements crave regular cleaning and lubrication, and the normal result of neglecting to get a watch cleaned is a watch stopped at full wind. Every bit the watch motion collects dirt and the oil dries upward, friction increases, so that the mainspring doesn't have the force to plow the lookout at the cease of its normal running period, and it stops prematurely. If the owner continues to wind and employ the lookout without servicing, eventually the friction force reaches the 'apartment' part of the torque curve, and speedily a point is reached where the mainspring doesn't have the force to run the sentinel even at full air current, so the watch stops with the mainspring fully wound. The watch needs service, simply the problem is caused by a dirty movement or other defect, not "overwinding".

Some other common cause of "overwinding" is that if a lookout is dropped and so the balance staff tin break and the scout can no longer run fifty-fifty when the mainspring is fully wound.

Cocky-winding watches and 'unbreakable' mainsprings [edit]

The mainspring of an automatic watch. The spring isn't firmly mounted on the left side, and will slip when fully wound.

Self-winding or automatic watches, introduced widely in the 1950s, use the natural motions of the wrist to keep the mainspring wound. A semicircular weight, pivoted at the center of the watch, rotates with each wrist motion. A winder mechanism uses rotations in both directions to wind the mainspring.

In automatic watches, motion of the wrist could proceed winding the mainspring until it bankrupt. This is prevented with a slipping clutch device.[15] The outer end of the mainspring, instead of attaching to the barrel, is attached to a circular expansion spring called the bridle that presses against the inner wall of the barrel, which has serrations or notches to concord it. During normal winding the bridle holds by friction to the barrel, assuasive the mainspring to wind. When the mainspring reaches its full tension, its pull is stronger than the bridle. Farther rotation of the arbor causes the bridle to sideslip along the barrel, preventing farther winding. In picket company terminology, this is often misleadingly referred to as an 'unbreakable mainspring'.[ citation needed ]

'Tired' or 'set' mainsprings [edit]

Later decades of use, mainsprings in older timepieces are constitute to deform slightly and lose some of their forcefulness, becoming 'tired' or 'set'. This condition is mostly found in springs in barrels. It causes the running time between windings to decrease. During servicing the mainspring should be checked for 'tiredness' and replaced if necessary. The British Horological Institute suggests these tests:[xvi]

- In a mainspring barrel, when unwound and relaxed, about of a good for you spring's turns should be pressed flat against the wall of the barrel, with only ane or 2 turns spiralling across the fundamental space to adhere to the arbor. If more than 2 turns are loose in the center, the jump may be 'tired'; with 4 or 5 turns it definitely is 'tired'.

- When removed from the barrel, if the diameter of the relaxed spring lying on a flat surface is less than 2½ times the butt diameter, information technology is 'tired'.

Power reserve indicator [edit]

The ability reserve is at the half dozen position on this automated spotter. Hither it is indicating that 25 out of xl hours remain

Some loftier-course watches have an extra dial on the face indicating how much power is left in the mainspring, often graduated in hours the watch has left to run. Since both the arbor and the barrel turn, this mechanism requires a differential gear that measures how far the arbor has been turned, compared to the barrel.

Unusual forms of mainspring [edit]

A mainspring is usually a coiled metallic spring, however there are exceptions:

- The wagon spring clock: During a brief time in American clockmaking history, coilable spring steel was not available in the United States, and inventive clockmakers congenital clocks powered by a stack of foliage springs, similar to what has traditionally served every bit a intermission spring for wagons.

- Other spring types are conceivable and have been used occasionally on experimental timepieces, such as torsion springs.

- Occasionally one finds an odd clock with a jump fabricated of material other than metal, such equally synthetic elastic materials.

Notes [edit]

- ^ a b c White, Lynn Jr. (1966). Medieval Technology and Social Change. New York: Oxford Univ. Printing. ISBN0-19-500266-0. , p.126-127

- ^ Farr, James Richard (2000). Artisans in Europe, 1300-1914. London: Cambridge University Press. p. 69. ISBN052142934X.

- ^ Milham, Willis I. (1945). Time and Timekeepers. New York: MacMillan. ISBN0-7808-0008-vii. , p.121

- ^ "Clock". The New Encyclopædia Britannica. Vol. 4. Univ. of Chicago. 1974. p. 747. ISBN0-85229-290-ii.

- ^ Anzovin, Steve; Podell, Janet (2000). Famous First Facts: A tape of starting time happenings, discoveries, and inventions in earth history. H.Due west. Wilson. ISBN0-8242-0958-three. , p.440

- ^ Usher, Abbot Payson (1988). A History of Mechanical Inventions. Courier Dover. ISBN0-486-25593-10. , p.305

- ^ Dohrn-van Rossum, Gerhard (1997). History of the Hr: Clocks and Mod Temporal Orders. Univ. of Chicago Press. ISBN0-226-15510-two. , p.121

- ^ Berthoud, Ferdinand; Auch, Jacob (2005). How to make a verge watch. Kingston, Tasmania: Richard Watkins. p. 218.

- ^ Blakey, William (2014). The art of making scout mainsprings, repeater springs and balance springs. Kingston, Tasmania: Richard Watkins. p. 55.

- ^ "Why practice mainsprings break?". Technical Note TD105. Hamilton Lookout man Co. Archived from the original on 2011-07-10. Retrieved 2007-10-08 . on NAWCC eHorology Virtual Museum Archived 2008-08-27 at the Wayback Machine

- ^ Bretscher, Ulrich (2007). "The Roskopf Watch". Ulrich Bretscher'south pocket sentinel page. Archived from the original on 2012-04-01. Retrieved 2007-12-07 .

- ^ De Carle, Donald (1969). Practical Picket Repairing, tertiary Ed. London: Robert Hale Ltd. ISBN0-7198-0030-7. , p.91

- ^ Milham 1945, p.105

- ^ a b Gainey, Michael. "You can wind a mainspring besides tight". Clock Myths. Master Clock Repair Gainey'due south website. Retrieved May 23, 2014.

- ^ De Carle 1969, p.90-91

- ^ "Workshop hints: mainsprings". British Horological Institute website. 1997. Archived from the original on 2009-04-26. Retrieved 2008-04-xx .

References [edit]

- One thousand.A. Berner 4-language Glossary, 1988 re-edition, courtesy FH, Federation of the Swiss Sentinel Manufacture, Bienne, Switzerland.

- Murray, Michael P. (2005-02-01). "Everything you ever wanted to know near clock mainsprings". Mike's Clock Clinic. Retrieved 2009-07-06 .

External links [edit]

- Federation of the Swiss Watch Industry Dictionary

Source: https://en.wikipedia.org/wiki/Mainspring

Post a Comment for "What Is Art Made of Springs and Gears Called"